Many people use the terms “surgical steel” and “stainless steel” interchangeably. However, although related, they are not the same thing. Understanding this distinction is crucial. After all, applications where hygiene, durability and biocompatibility are non-negotiable, such as in healthcare environments or the food industry, depend on this clarity. In this article, we’ll unravel the real difference between surgical steel and stainless steel, clarifying myths and facts.

Stainless Steel: The Basis for Resistance and Versatility

Stainless steel (or simply stainless steel) is actually a vast family of metal alloys. Its main characteristic is its remarkable resistance to corrosion. The presence of at least 10.5% chromium in its composition confers this property. When chromium is exposed to oxygen, it forms a thin, invisible passive layer on the surface of the metal. This layer acts as a protective barrier against oxidation (rust) and other corrosive agents.

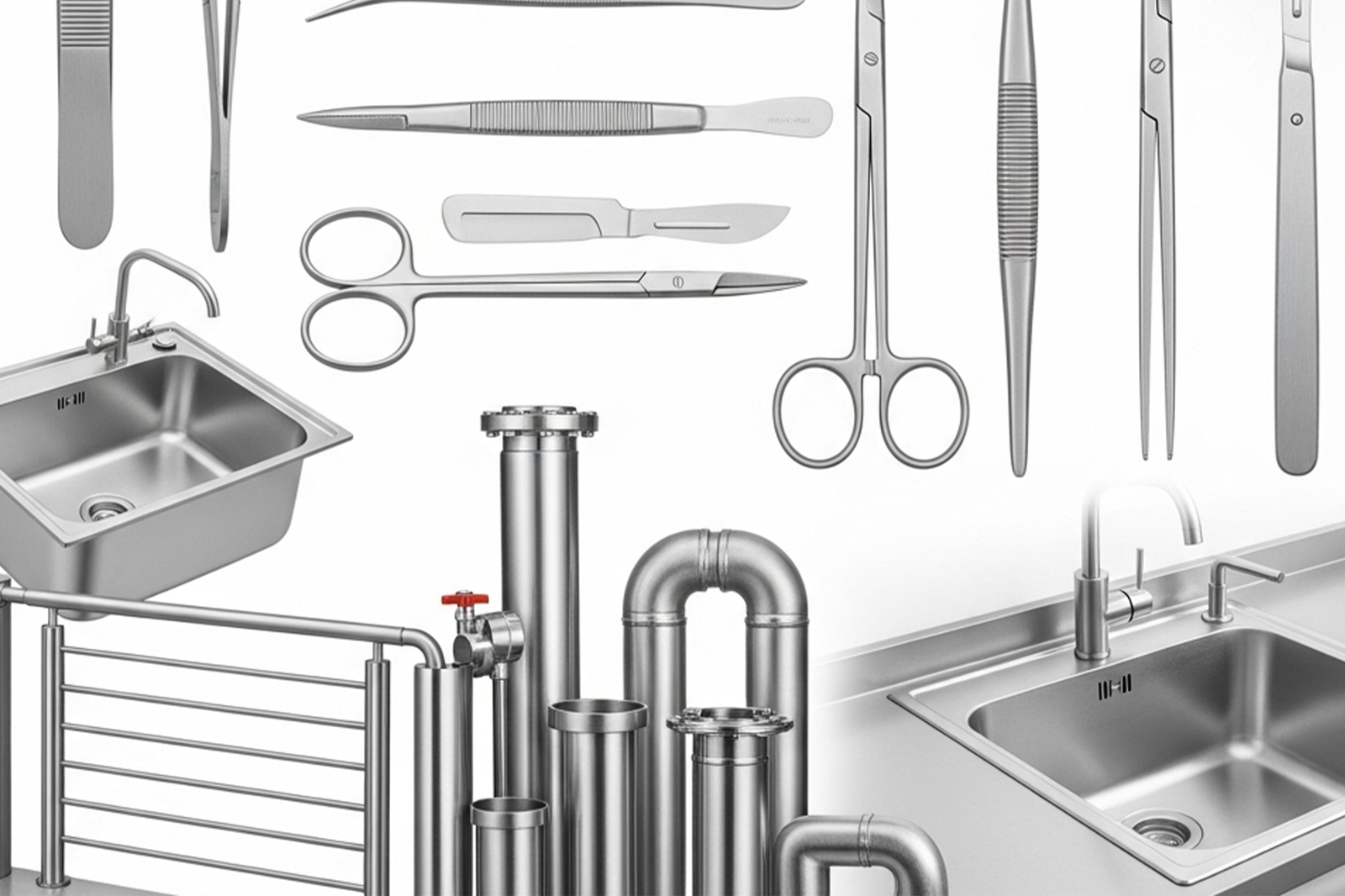

There are several variations of stainless steel (such as the 304, 430 and 316 series). Each one has slightly different compositions and properties. Consequently, they are suitable for a variety of uses: from domestic utensils and kitchen sinks to heavy industrial equipment and building facades. Its ease of cleaning, durability and modern aesthetics make it an extremely versatile material. It is therefore widely used in numerous sectors. To find out more about the general specifications of stainless steel, you can consult the Brazilian Stainless Steel Association (Abinox).

Surgical Steel: Stainless Steel Elevated to the Medical Level

The term surgical steel refers to a specific type of stainless steel. Manufacturers design and process it to meet the very high standards demanded by the medical, dental and implant industries. AISI 316L stainless steel is the best known and most widely used. The letter “L” stands for “Low Carbon”, a crucial characteristic for this application.

The main difference between surgical steel and other types of stainless steel lies in its chemical composition and processing:

- Low Carbon: The reduced carbon content in 316L minimizes the formation of carbides during welding and heat treatment. This, in turn, significantly increases its resistance to intergranular corrosion. This characteristic is vital as it prevents failure in aggressive environments such as the human body.

- Molybdenum addition: Surgical steel (such as 316L) contains molybdenum in its alloy. This element provides superior resistance to pitting and crevice corrosion, especially in environments with chlorides, such as salt water or bodily fluids.

- Purity and Biocompatibility: Surgical steel undergoes more rigorous manufacturing processes, such as vacuum melting. Manufacturers thus guarantee exceptional purity and the absence of contaminating elements. This purity is essential for its biocompatibility, i.e. its ability to be tolerated by the human body without causing adverse reactions, inflammation or rejection. Consequentlyand,, it is safe for implants and instruments that come into direct contact with tissues and biological fluids. For more information on the importance of asepsis in hospital environments, check out our blog on sinks for hand asepsis.

- Hypoallergenicity: Surgical steel generally has a controlled and, in some cases, reduced nickel content. This aims to reduce the likelihood of allergic reactions in sensitive patients.

The Essential Relationship: All Surgical Steel Is Stainless, but Not All Stainless Is Surgical

The main conclusion is clear: all surgical steel is a type of stainless steel. However, not all stainless steel has the characteristics and purity necessary to classify it as “surgical”. Surgical steel is therefore a specialized version of stainless steel, optimized for the extreme demands of the medical environment. Patient safety and the integrity of the material are non-negotiable.

In short, while ordinary stainless steel is excellent for many everyday and industrial applications, surgical steel is the mandatory choice for surgical instruments, orthopaedic and dental implants. It is also essential for other devices that require maximum performance in biological environments.

See more: Why use stainless steel equipment for industrial kitchens?